Forestry technology: Robust for forests and woodland

Whether thinning or clear-cutting - you can't do forestry without the right machines.

Almost a third of Germany's land area is forested. The task of forestry is to manage and maintain this area sustainably. According to the principle of “protection through utilization”, the tree population is renewed, maintained and also thinned out by forest managers in order to ensure a healthy and sustainable forest area. Heavy machinery is irreplaceable in silviculture: safe and efficient work in the wood is only possible if forestry machinery supports people.

Machines in forestry

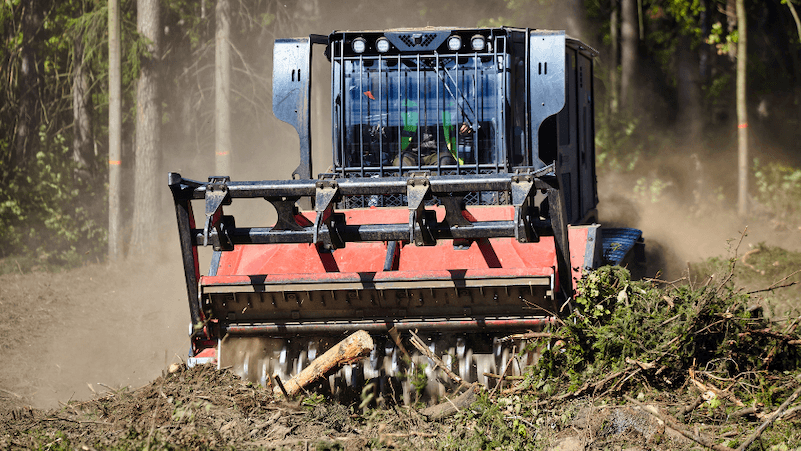

Machines used in forests and woodland are exposed to particularly harsh conditions: Solid wood as working material, flying or falling tree parts and poorly constructed paths are just some of the difficulties the machines face. For this reason, forestry technology must be significantly more robust than comparable agricultural machinery. The issue of safety is also very important in the forest. Particular attention must be paid to the safety of the driver, as flying pieces of wood or falling trees can cause extremely serious injuries. The maneuverability of the machines must also be taken into account: Smaller, maneuverable machines have proven to be particularly effective in confined stands.

Which machines are used in forestry?

Various large machines are used in the forest to support the workers. The most characteristic of these are forestry tractors, harvesters and forwarders. While the forestry tractor can be used for various tasks, the harvester is a highly specialized machine that fixes trees, cuts them down, delimbs them and places them for transport. The forwarder is the classic machine for hauling the timber harvested by the harvester out of the forest. Alternatively, there is the skidder or rope tractor, which can also be used to transport timber. In addition to the large machines, smaller machines are also used, such as the forest mulcher, tree stump grinder, log splitter & wood chipper or the automatic saw splitter.

In a nutshell: Machines in forestry

These self-propelled machines are used in forestry:

- Forestry tractor

- Forwader

- Harvester

- Skier

Other forestry equipment:

- Stump grinder

- Forest mulcher

- Wood chipper

- Wood splitter

- Automatic saw splitter

Our most popular machines in the forestry technology sector

Zanon

Mulchgerät TF/DT

35.650,00 €

Zanon TN/DT Special

Mulching in the forest? No problem at all with the TN/DT Special from Zanon. With its flails, the robust forestry mulcher reliably shreds vegetation with trunks up to 40 cm in diameter and still always produces uniform shredding results. Thanks to a front guard with double-row chains and center flaps as well as a rear chain guard, the mulcher offers maximum safety from flying pieces of wood when working in the forest.

Kubota

L1-522DR

23.445,38 €

27.810,00 €

Kubota L1-552

Small but powerful - with its 51 hp four-cylinder engine, the Kubota L1-552 is a small powerhouse that is ideal for use in the forest. Thanks to its compact design and the transmission with eight forward and eight reverse gears, it can be maneuvered particularly flexibly and maneuverably even through narrow forest paths. A particular highlight is the powerful hydraulic performance of the compact tractor, which makes it easy to use even heavy attachments.

JCB

Fastrac 4220 iCON

193.500,00 €

219.317,00 €

JCB Fastrac 4220 iCON

With its four equally sized tires and the additional attachment space behind the cab, the JCB Fastrac 4220 iCON is not only a real eye-catcher, but also ideally suited for use in forestry. Thanks to the numerous attachment compartments, the machine can be easily converted with various attachments for forestry work. With its 218 hp, the machine also offers plenty of power for all standard forestry work.