Conditioner for mowers: Effect, advantages & areas of application

Disc and drum mowers are often available with or without conditioners - we explain the difference.

When looking for a mower, in addition to the question of what type of mower you need, you also need to ask yourself whether you prefer a mower with or without a conditioner. Conditioners are often used in mowers to additionally process the mowed material. But what exactly is their effect and what are the advantages of using conditioners? We explain.

What is a conditioner on a mower?

A conditioner is an additional device that is often integrated into the mower to mechanically condition the crop once again. The conditioner breaks through the natural wax layer of the plants, which normally protects them from drying out, by crushing or bending them. The additional processing of the plant breaks through this protective barrier and increases the drying rate of the crop.

What are the advantages of conditioners?

The biggest advantage of conditioners for mowers is related to the drying process of the crop. As the conditioners break through the wax layer of the plant, the drying of the crop is significantly accelerated. Depending on the intensity of the conditioning, a drying advantage of up to 20% can be achieved. As a result, the frequency of turning passes can be reduced or, under certain circumstances (e.g. when using an intensive conditioner to create a wilted silage), the rotary hay rake can be dispensed with altogether. The conditioner also reduces the weather risk, as the crop can be collected earlier.

The use of a conditioner can also have a positive effect on the fermentation quality of the silage and lead to a reduction in the formation of acetic and hydrocyanic acid. The use of an intensive conditioner in particular shows a significant increase in fermentation quality. Tests also show an increase in the digestible mass and energy concentration in the silage. However, there are also advantages in hay production: In hay drying systems, the drying time is reduced by up to 40% if the crop has been conditioned beforehand.

Advantages of conditioners

- Faster drying process

- Reduction of turning cycles possible

- Positive effect on fermentation quality

- Increase in digestible organic mass (silage)

- Increase in energy concentration (silage)

- Faster drying in hay drying systems

What are the disadvantages of conditioners?

Unfortunately, reconditioners do not only have advantages: The economic aspects in particular must be taken into account. On the one hand, the additional costs of a mower with conditioner compared to a normal mower can amount to several thousand euros. In addition, mowers with conditioners are heavier, which can put a strain on the front axle, especially with front mowers, and have a higher power requirement on the PTO shaft.

Another major disadvantage is the field losses. In grass crops, conditioners lead to 0.1 to 0.2 dt DM/ha more crumbling losses. In clover crops, this value can increase three to fourfold if a tine conditioner is used. It is therefore important to choose the right conditioner and adjust it appropriately to minimize crumbling losses. In the case of soiling, the soil is distributed more intensively in the forage, which is why particular attention must be paid to the correct mowing height when mowing with the conditioner. In addition, conditioning in rainy weather has the opposite effect: the broken wax layer causes moisture to penetrate the mown crop more quickly, resulting in longer drying times and higher waxing losses.

Disadvantages of conditioners:

- Higher purchase price

- Load on the front axle (front mower)

- Higher power requirement

- Higher crumbling losses

- Washing out losses & long drying times in the rain

What types of conditioners are there?

In agriculture, conditioners are roughly divided into different categories. Firstly, a distinction is made between mower conditioners and intensive conditioners. The former are usually integrated into the mower and are in turn divided into two different designs: Flail or tine rotors and roller conditioners. Intensive conditioners are machines that have at least two or more tools, some of which even work in opposite directions. This significantly increases the conditioning effect.

Flail or tine rotors

Conditioners consisting of a flail or tine rotor have a more percussive effect. They throw the crop over a friction plate or a metal comb, which bends the stalks and breaks through the plant's wax layer. The tines can be rigidly mounted and made of plastic or oscillatingly mounted and made of steel. The conditioning intensity can be varied by the rotor speed and the distance between the tines and the friction plate or metal comb. It is particularly suitable for stalk-rich crops such as grass.

Roller conditioner

In contrast to the tine rotor, the roller conditioner has a crushing effect. The crop is conveyed between two profiled steel or plastic rollers and the wax layer is destroyed by the rubbing action. The conditioning intensity of roller conditioners can be determined by the contact pressure between the two rollers. They are particularly suitable for leafy crops, e.g. legumes or grass crops with a high proportion of clover.

Intensive conditioner

With intensive conditioners, the crop is forced through two or more tools that break up the wax layer of the plant. A profiled roller is often used to bend the crop, while an additional brush, for example, further conditions the leaves and stalks. Due to the high degree of conditioning, intensive conditioners are almost exclusively suitable for pure grass stands.

Which conditioner for which application?

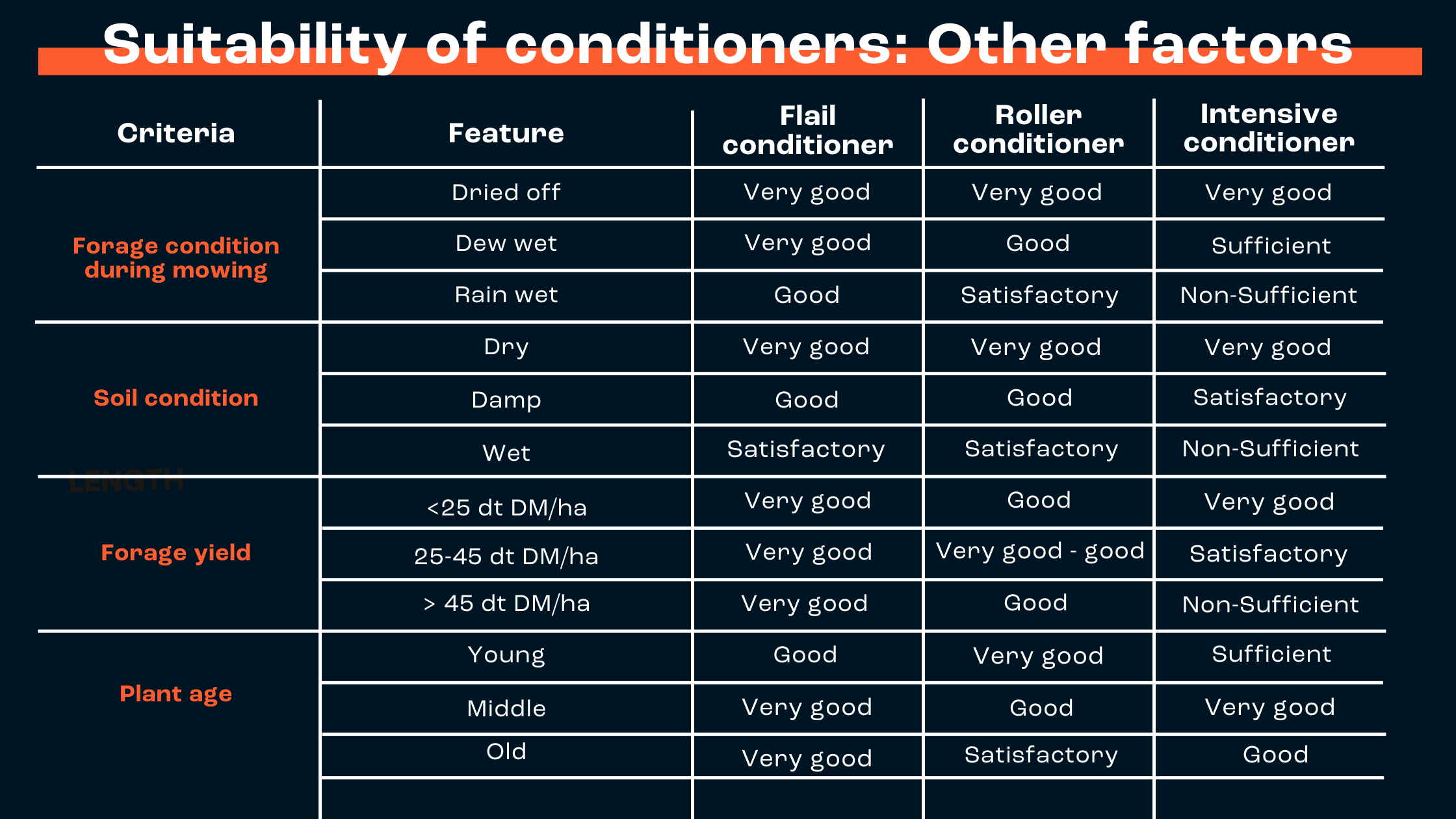

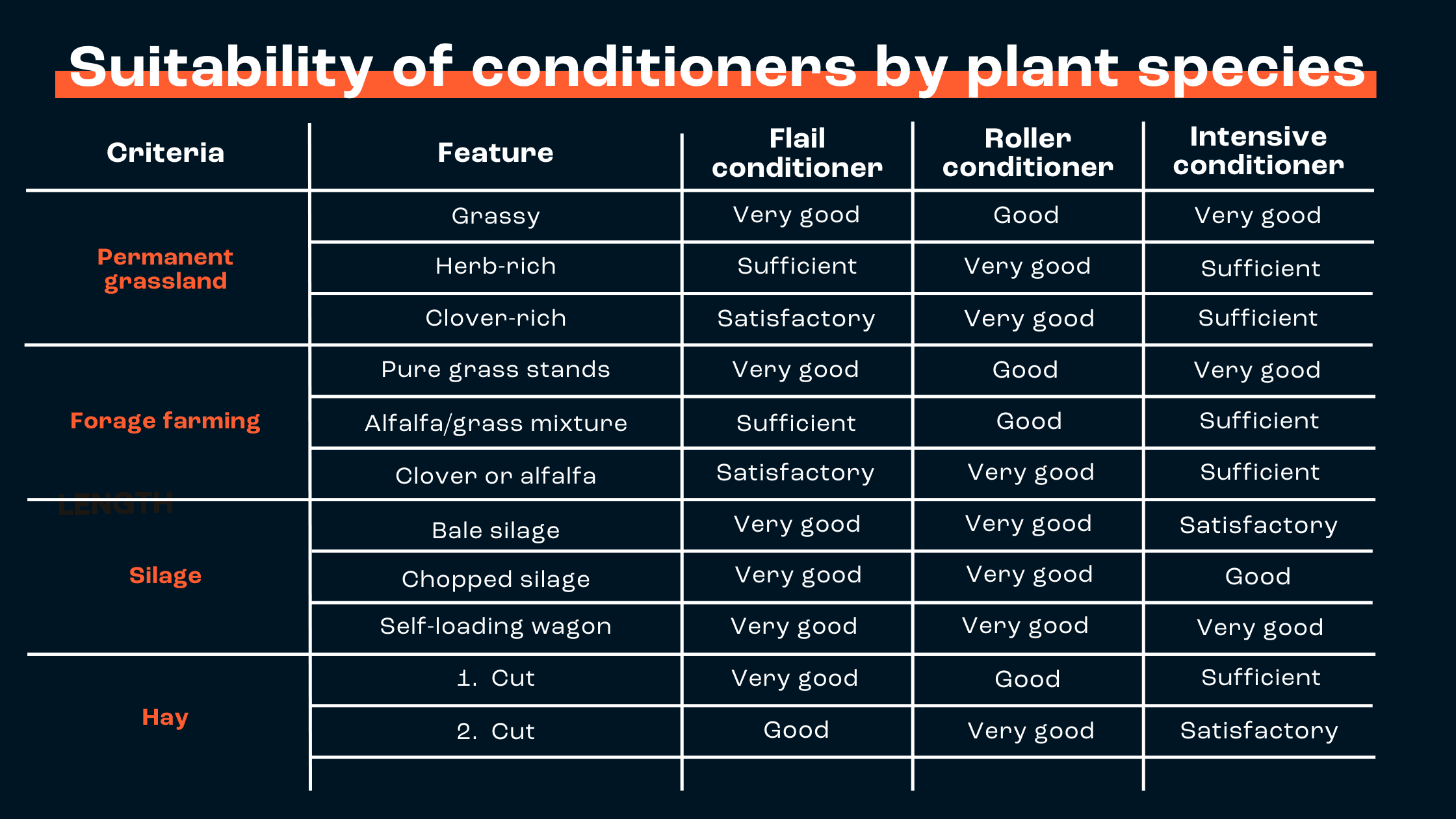

Depending on the area of application, different conditioners are more or less suitable for processing the mowed material. On the one hand, it depends on the type and intended use of the grassland growth. For example, the optimum conditioner for a herb-rich meadow for hay production differs from a conditioner for high-energy silage for dairy cattle.

However, forage yield, moisture, soil condition and plant age can also make a difference. The typical local conditions should therefore also be taken into account when selecting the optimum conditioner for your crop.